|

You can also

download the Annual Report

Annual Report

The 2024 Annual Report highlights the significant projects completed at the Gloversville Johnstown Joint Wastewater Treatment Facility (GJJWTF). Routine assignments such as tank cleaning, instrument calibration, laboratory analysis, sample collection, general maintenance and upkeep, while important, are not identified in this report. General statistics are included to illustrate additional activities at the facility.

O & M expenditures totaled $6.39 million for 2024.

The adopted budget was $6.88 million, which includes Insurance

Claim recovery of $1.19 Million. Fund Balance at year’s end was $472,855.

| Electrical Synopsis: |

|

|

| |

Generated |

2,230,262 kilowatt hours (↓)

-- 60.7% |

| |

Purchased |

2,947,481 kilowatt hours (↑) -- 801% $192,327 ($0.07) (↑)

- 430% |

| |

Sold |

185,846 kilowatt hours (↓) --

80.7% $6,374 ($0.034) (↓) - 86.0% |

Cogen's historically produced all GJJWTF’s electrical power needs and sold excess power.

The facility experienced an Insurable vehicle accident Impacting the High Yard Control Building on February 29, 2024, requiring all Cogen Units from service by order of National Grid on March 3, 2024. National Grid Locked Out all three Cogen Units and on October 23, 2024, National Grid removed locks and released units to full service.

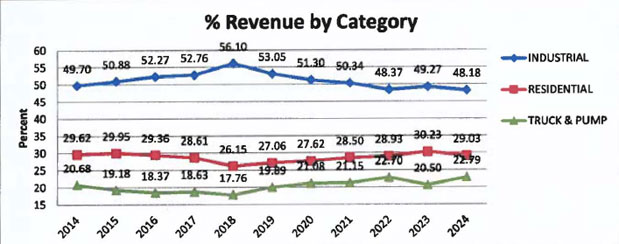

O & M revenues totaled $6.39

million during 2024. The Industrial contribution was 48.48%, Residential

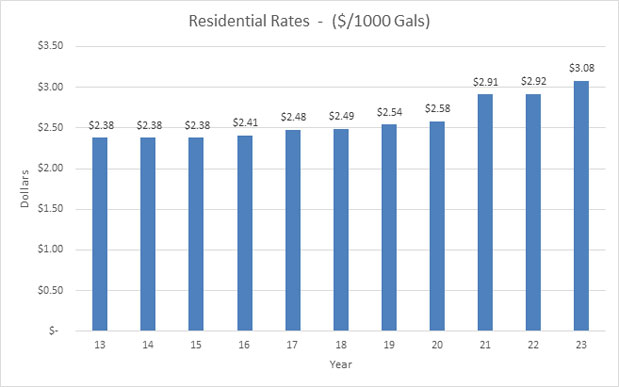

29.03% and Trucked/Pumped waste and miscellaneous revenue totaled 22.79%. The industrial sewer rate effectively remained constant while residential rates were increased by 10.8 percent. Use of $317,015 from the Rate Stabilization Reserve Fund helped to minimize the rate increase.

Belt Filter Presses operated 3,325 hours producing 17,749 wet tons of sludge. Fulton County Department of Solid Waste received $603,466 to accept the sludge.

The Dairy Industry accounted for 49.17% of the total O&M revenue collected. Combined, FAGE USA Dairy Industry, Inc. and Euphrates Inc. pumped a total of

29.4 million gallons of whey to the Anaerobic Digester and

214.5 million gallons of washwater to the Contact Adsorption Settling Thickening (CAST) system for processing via two dedicated pipelines.

The foundation of GJJWTF success is the support of the Gloversville-Johnstown Joint Sewer Board (GJJSB) and the work of its twenty-seven (27) employees. The conscientious efforts by all GJJWTF employees on days, nights, weekends, holidays, during severe weather, and often in an inhospitable environment, the facility continues to operate and meet its wastewater

discharge SPDES permit requirements.

The employee names (as of 12/31/24) are as follows:

|

Barbara

Allen

|

Kenneth

Gifford

|

Hilary

Ruzycky

|

|

Daniel

Ashcroft

|

Haleigh

Grubb

|

Victor

Rzesos

|

|

Harry Brand

|

Matthew

Handy

|

John

Samples

|

|

Steven

Burns

|

Ronald

Horton

|

Adrienne Slade

|

|

Owen

Chizek

|

Reuben

Kennedy

|

Aaron

Tubbs

|

|

Ian Colvin Marincic

|

Ty Leonard

|

Michael VanAlstyne

|

|

Lacie

Folts

|

Mark Levendusky

|

Christopher VanAuken

|

|

Bruce

Gardner

|

Richard Pedrick

|

Christian

Walters

|

|

Darlene Gaugler

|

Tyler Pettit

|

Robert Yaggle

|

PERSONNEL

2024 Joint Sewer Board

Members

- Chair -

Christopher Vose

- Vice Chair -

Donald Schwartz

- Secretary -

Eric Parker

- Board members - Michael Stover, John Rizzo and

Bobbi Trudel

Licensed Operators

One (1) NYSDEC Grade 4A licensed Chief Operator

Three (3) NYSDEC Grade 3A licensed Wastewater Treatment Operators

New Hires

- Harry Brand, Manager-Wastewater Programs

- Robert Yaggle, Chief WWTP Operator

- Michael VanAlstyne, WWTP Operator

- Adrienne Slade, Account Clerknt

Left Employment

Retirements

Sick Days

Four (6) employees utilized three (2) sick days or less during 2024. The names of those employees are as follows:

- Harry Brand*

- Adrienne Slade*

- Lacie Folts

- Robert Yaggle*

-

Bruce Gardner

- Haleigh Grubb

*Only Employed Partial Year

Work Related Injuries

One (1) work related injury reported in 2024, which resulted in Lost Time from work.

- Employee fell while exiting the Skid Steer, impacting leg on bucket, resulting in a

deep tissue bruise of upper thigh, restricting duty.

NYSDEC Compliance

- Effective June 17,2024 the GJJWTF entered into a Consulting Agreement with a Certified

4A Wastewater Operator who had previously been employed at the facility. He was onsite

a minimum of 30-days per calendar quarter, in accordance with NYSDEC Technical and

Operational Guidance Series (TOGS) Section III.B. Special Guidance on Selected

Segments of Part 650, Plant Coverage III.B.2.a. This addressed the NYSDEC's

unsatisfactory items identified during the 2023 Annual Permit Inspection and was required

to be completed prior to July 3, 2024.

- June 29, 2024, the facility experienced a permit limit exceedance with an Effluent

Settleable Solids sample result was 0.4 mUL, while permit limit is 0.1 milL. A Report of

Noncompliance was submitted to NYSDEC via email 7/1/24, no further actions required.

- August 17, 2024, the facility experienced a permit limit exceedance with an Effluent

Settleable Solids sample result of 0.5 milL, while permit limit is 0.1 milL. A

Report of Noncompliance was submitted to NYSDEC via email 8117/24,

no further actions required.

- Auguust 20, 2024 the facility received the WET analysis report for the test period 8/6/24 -

8/12124, the lab report indicates our TUc(IC25repro) = 1.71 for Freshwater Invertebrate,

Ceriodaphnia Dubia; the permit Action Level is 1.3 for the period June - August. Email

notification was made to NYSDEC which included the report. NYSDEC has indicated no

further action at this time, but following a complete review of the report, the facility may be

required to conduct additional WET testing

- November 14, 2024 - NYSDEC conducted the annual on site comprehensive SPDES plant

inspection. The facility was assigned an overall rating of Satisfactory.

- December 9, 2024, received notification from NYSDEC indicating that an additional year

of quarterly Chronic testing using only the more sensitive invertebrate species is required

at Outfall 001 due to the August 2024 test failure. The required testing must be initiated

within 60 days following this notification

Odor Complaints

Two (2) odor complaints reported in 2024.

- June 11,2024 @ 11 :45 pm, lasting for 1-hour, complaint made directly to NYSDEC

- August 22,2024 @ 10:31 pm, complaint made to the facility by a South Melcher St city

resident, indicated odor started approximately 8:30 pm and worsened resulting in the

complaint at 10:30 pm.

New Septic Haulers

FOIL Request

On 8/19/24 the facility received a FOIL request on behalf of the Hudson and Mohawk Rivers Leachate Collaborative, requesting all data associated with the facility's policy and procedures

governing its acceptance of leachate from landfills. On 8/22124, GJJWTF staff responded to the

FOIL request confirming the receipt of the request and that we would provide the available

information within 20-days. All requested data was transmitted, and receipt confirmed via email

on 9/3/24, no further request has been received.

OPERATIONS AND MAINTENANCE

-

Continue to work through the historical problem of the process control fiber communication

network (SCADA) lack of reliability and limited records. A couple vendors have been

onsite to address system failures and restore the network but did not address the root

problem of overall network reliability and documentation. General Control Systems has

been selected to conduct a complete network review, document current SCADA Network

arrangement, and provide a proposal to increase overall network.

-

January 2024, Cogen #1 experienced a major head failure resulting in cylinder #1 piston

damage. Cogen #1 was due for a Top End Overhaul in 2024, so a decision was made to

complete the Top End Overhaul in conjunction with the head repair.

-

On Feb 29th 2024, a unmanned running truck with roll off dumpster rolled down the hill

from the Sludge Building and impacted the High Yard Control Building, destroying the

building and its contents.

The control building contains all the Protective Relaying and Communication equipment

required to support the National Grid Interconnection, allowing the facility to operate its

Cogen Units and export power. On March 31d the Cogen Units were taken out of service

and High Yard was modified to allow the facility to be energized from the National Grid

System, without the Control Building. Part of this temporary arrangement, National Grid

required the facility's Cogen Units to be Locked Out until a new Control Building was

erected, and all protective relaying and communication equipment had been upgraded to

current standards. On October 23, 2024 Construction and installation of required

equipment was completed to the point that satisfied National Grid's requirement to allow

the Cogen Units to be retumed to service. Due to equipment lead times, the final metering

equipment and Remote Telemetry Unit (RTU) will not be received or installed until

sometime in 2025. An agreement was reached with National Grid to allow the operation of

the COGEN Units prior to this being completed.

This event was an insurable event as both property damage and business interruption.

On August 28, 2024, a Property Damage settlement was reached with NYMIR in

the amount of $1,488,621.39

Business Interruption claim has not been settled, and the total insurable amount

is being determined, as of December 31 , 2024, the facility has received $100,000

for extra expense associated with the loss.

-

On April 9, 2024 the facility experienced a significant slope failure of the facility's northside

along the Cayadutta Creek, impacting approximately 350 feet of the slope. This failure

also posed a potential risk to the facility's high voltage duct bank's integrity, which runs

adjacent to the slope. Greenman·Pedersen, Inc. (GPI) was contracted to develop an

engineering solution, and navigate all regulatory and permitting processes required to

stabilize the slope failure. A proposed solution was developed, reviewed by the Army Corp

of Engineers, and a Nationwide Permit was issued on August 22, 2024. An open bid was

awarded to Carver Companies on October 91h, in the amount of $1,032,145. GPI was also

retained as Project manager increasing their total cost to $225,000. A BAN was issued to

the City of Gloversville in the amount $1 ,256,945, to cover the cost associated with the

slope stabilization project. The project was significantly completed on 12/20/24. Carver

will return in the spring once conditions facilitate final clean up and road repairs.

This Project was awarded the APWA Capital Branch project of the year for the

Gloversville·Johnstown Joint Wastewater Treatment Facility Slope Failure project, in the

emergency construction category, less than $5 million division.

-

On April 13th the primary Aeration Blower (Turblex) had a Class 1 Service (Major Overhaul)

completed by the blower OEM (Howden), at 71,999.9 hours.

-

On April 26th Milton Cat, High Voltage Electrical Services and Amaha Electric completed

the upgrade project consisting of the Installation of the auto transfer switch of the UV

Disinfection System to the Emergency Diesel Generator (EDG) upon a loss of normal

power. This addresses the NYSDEC's unsatisfactory items identified during the 2023

Annual Permit Inspection and was required to be completed prior to May 1, 2024. The UV

System is required to be continuously in service from May 1st through October 31st, in

accordance with the facility's SPDES Permit.

-

A review of PBS Registration determined that one of the facility's Registered Tanks was

incorrectly removed from the PBS Registration following the 2021 NYSDEC PBS

Inspection. The Inspector was shown the incorrect tank (portable Godwin Pump tank), and

not registered Tank # 006. On 5/24/24 notified NYSDEC and revised the PBS Registration

to include Tank #006. Tank #006 required modification to bring it in compliance with

regulations, which required a secondary containment to be fabricated and installed by

facility staff, along with acceptable overfill protection. NYSDEC indicated they will provide

30-days to complete required modification and update PBS Registration, all was

completed.

-

On 5/27/24, at 11:18 P.M. the fire alarm system called a false alarm to the Johnstown Fire

Department. Another alarm called out at 4 A.M. the next morning. Zone 4 in Recirculation

Building was temporarily disabled. Fire Security & Sound Systems of Latham installed two

new heat detectors and replaced a bad resistor.

-

On 6/20/24, a new replacement digester gas mixer compressor (NASH) was ordered from

NES. Currently the two mixers in service are both experiencing excess seal leakage, while

redundant mixers, neither are 100% reliable. The cost and lead time for a refurbishment

justified the purchasing of a new unit. Upon receipt of the new mixer, it will be installed and

facilitate the refurbishment of the one removed. The new compressor is anticipated to be

received in February 2025.

-

On 6/29/24 Precision Industrial Maintenance jet cleaned and vacuumed the Wash Water

wastewater pipe from Manhole #4 to the Cast Headworks. This line is a dedicated line supporting FAGE and Euphrates dairy process. To support this cleaning process Wash

Water discharges would have to be minimized. An agreement was reached with FAGE to

complete this work on a weekend, with FAGE agreeing to pay all the Incremental cost

associated with performing the work outside normal working hours. This cleaning was

past due, and posed the risk of surging the wash water line manhole which would result in

a reportable release. This will be completed annually moving forward.

-

On 9/5/24 HVES returned and installed All 4 EATON High Yard breakers following rebuild

required due to rodent damage, which made them non-serviceable. Research found that

this same switch gear experienced rodent damage back in October 2019. Efforts were

made to identify various points of entry for the rodents and installed sealant to mitigate any

future rodent damage.

-

On 9/5/24 HVES & OMAHA Electric made the connection between MCC B in Aeration

Building and the EDG Disconnect which facilitates back feeding the north side of the facility

in event of a power outage. The decision was made back in March not to take power out

of facility to make connection. This work was completed during the National Grid required

Line Outage.

-

On 9/17/24 facility staff commenced the cleaning and inspection of the Aeration Tanks.

The normal periodicity of Aeration Tank cleaning and Inspection is 3-years, however the

last time any cleaning was completed was in 2014. Upon draining the first tank, found an

excess amount of shells and grit in the tank, significantly increasing the time required to

complete cleaning. It was also found that the air diffusers were not providing design flow,

which reduces the efficiency of the tank performance. Investigation found the diffuser

internal orifices were blocked; all orifices were cleared. Only Tanks #1 & #2 were

completed in 2024, Tanks #3 & #4 will be completed in 2025.

-

During the week of November 4th, following the Cogen Units being retumed to service,

the decision was made to have Milton Cat, HVES and Prime Automation, to bring a Load

Bank on site to allow for additional tuning of the Cogen Units control and load sharing,

without being connected to the physical system. Historically the ability for the units to

operate in island mode and load sharing was not reliable or suffiCiently stable. Additionally,

the Black Start function was never commissioned. This was completed, significantly

improving the system operations and reliability.

-

On 12/28/24 facility staff and Precision Industrial Maintenance commenced the inspection

and cleaning of Whey Tank #1 . After 6-days of removing the solids (cheese Particulate),

emptying approximately 80% of the solids, it was decided to stop and place the tank online,

due to the inability to continue to manage Whey flow. The Tank will be reopened, and the

cleaning will be completed in October. Approximately forty-four truckloads of 2,750 gallons

each (121,000 gallons) were removed from the tank and processed through the Screening

Building. Facility staff worked through several screening issues with the grit classifiers,

grease compactor, and plugged pumps. Approximately 108 tons of debris were removed

and transported to the Fulton County Landfill. FAGE agreed to pay for the Incremental cost

associated with working on the weekends, to minimize the impact on their process. The

tank had not been opened for inspection or cleaning in almost 4-years, at a minimum this

maintenance must be performed every two years.

GRANTS & LOANS

Continue to work with L&S Energy Services, Inc. and NYSERDA to finalize Measurement &

Verification (M&V) data for performance year 7 (July 2022 - July 2023) & 8 (July 2023 - July

2024) of Cogen Engine No.3, per NYSERDA grant disbursement requirements. L&S Energy

Services, Inc. has recommended that M&V Year 7 PIP be based on 1,287,714 kWh, awaiting

NYSERDA review and approval.

NBT Bank Purchased a 1-year BAN in the amount of $1,256,945 at 4.25%, being offered by the

City of Gloversville on behalf of GJJWTF to fund the Slope Stabilization Project.

COMPLIANCE MONITORING AND TESTING

Completed annual reviews of the following lab manuals:

Laboratory Quality Manual

Laboratory Test Method SOP Manual

Monitoring Field Activities SOP Manual

Administrative and Quality Procedures SOP

POTW sludge that was hauled to GJJWTF during 2024 was analyzed for T. Metals, and T.

Phosphorus as well as the full TCLP scan.

Chain Gauge was replaced and re-zeroed on the Union Ave Bridge used for SPDES required

stream flow measurement.

New QC limits for all parameters analyzed at GJJWTF were calculated in house by lab director.

PFOAS sampled on the BFP prior to the addition of sand and on the Final effluent.

Lab Continues to monitor industries for all priority pollutants once every three years.

Whole Effluent Toxicity (WET) on facility effluent was sampled during all 4 quarters in 2024. Third

quarter results exhibited unacceptable chronic toxicity after mixing with the Cayadutta receiving

water. GJJWTF is now required to monitor for WET for only the more sensitive invertebrate

species for four quarters in 2025.

Lab Director calculated the annual Minimum Detection Limits (MOL) for NH3 and dissolved

sulfide.

Lab staff calibrate and maintain GJJWTF's 4 confined space meters. Lab director would defective

sensors.

Completed the 2024 annual NYS DOH ELAP internal laboratory audit.

The Proficiency test (PT) sample result for COD submitted to NYS DOH ELAP during July 2024

was found to be unacceptable. COD data is not submitted to NYS DEC and Is used for process

control only. GJJWTF still holds certification for COD. Currently, no corrective action is required

due to a history of successful analysis. However, GJJWTF has enrolled its colorimeter with

8

HACH in an exchange program for the entire year. If there is a concern with the meter, HACH's

tech support will assist, and if needed, will send out a loaner meter for GJJWTF to use while the

meter in question is mailed back to HACH for repair. All other PT sampling results submitted

during 2024 which would include BOD, CBOD, TSS, TKN, NH3, Dissolved Sulfide, Settleable

Solids, and Fecal Coliform were found to be acceptable.

Submitted annual DMR QA 44 to EPA. PT scores from GJJWTF including the subcontracted lab

PT scores make up an annual DMR QA. The only sampling results required to be submitted to

the DMR QA study are for the parameters listed in GJJWTF's SPDES permit.

The industrial pretreatment program's NYS SPDES required semiannual reports have been

submitted to EPA and DEC.

Annual ethics and data integrity training of all lab and monitoring personnel took place during

December 2024.

Submitted Mercury Minimization Plan to DEC in March of 2024. This plan contains quarterly

SPDES required low-level mercury analysis on plant effluent and any other activities that

GJJWTF takes part in to minimize Hg from entering the treatment facility's waste stream.

All industrial and facility flow meters checked for accuracy throughout the year.

All monitoring equipment located within GJJWTF and the cities of Gloversville and Johnstown

have been maintained and calibrated during 2024. Specifically, the calibration of flow meters,

replacing sampling pumps, maintaining probes and meters associated with pH, D.O., %

transmittance, ORP, vacuum pumps and conductivity. HACH SC200 control interfaces are

maintained that control D.O. in the aeration basin, pump sodium hypo chloride and sodium

hydroxide in the odor scrubber, and control the % transmittance for UV disinfection.

The following annual contracts have been maintained throughout 2024: reagent water services,

analytical balance calibrations, temperature verification, and outside lab services.

Issued permits to 10 Industries in Johnstown and 9 industries in Gloversville for 2024.

Semi-annual notarized responses from industries categorized as metal finishers have been

received. Epimed International, Inc. and Lippert components explain that to the

best of their knowledge no TTO has been discharged.

Two Notice of Violations for pH were issued to industries during 2024.

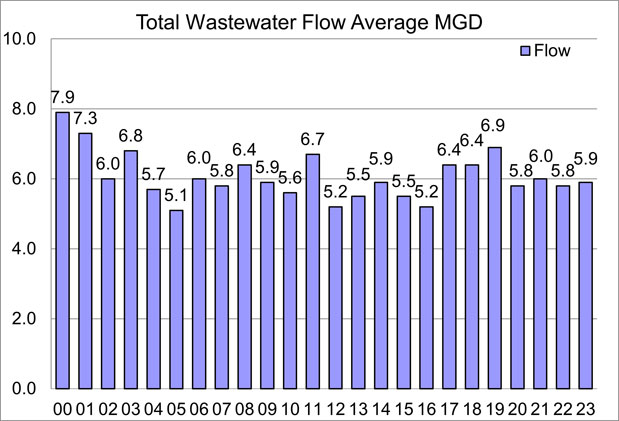

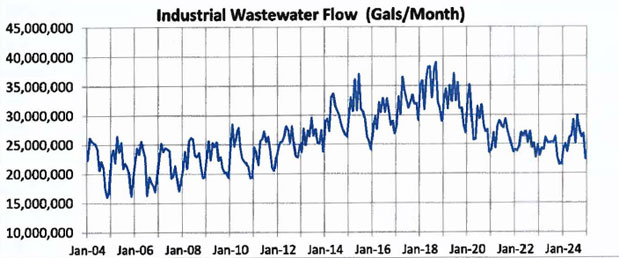

TOTAL WASTEWATER FLOWS

Historically. the total flow of Influent wastewater to the Plant is relatively constant.

Total Industrial Flows Increased 7.3~o in 2024.

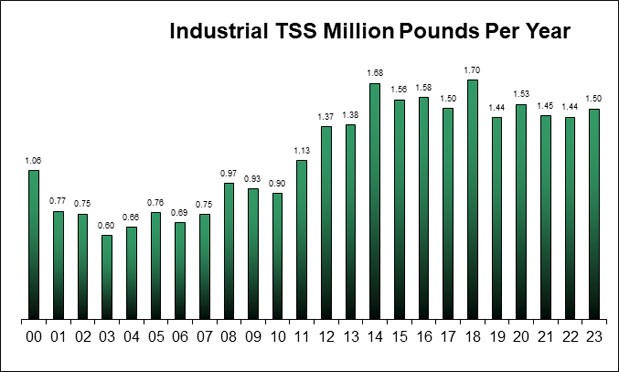

Industry: Total Suspended Solids (TSS) Total Suspended Solids (TSS) increased 32.7% in 2024.

Industry:

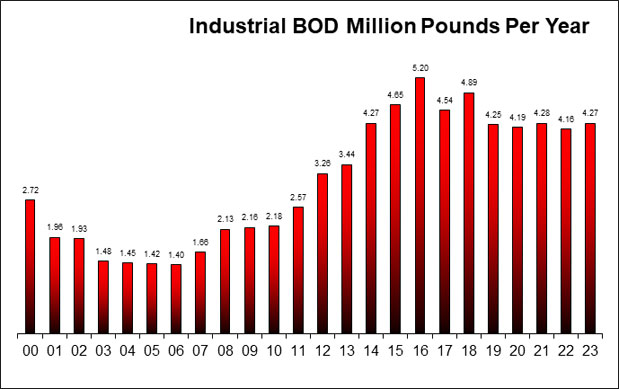

Biochemical Oxygen Demand (BOD) increased 26% in 2024.

Industry:

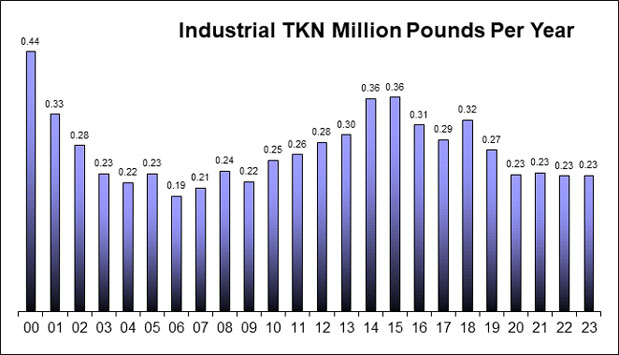

Total Kjeldahl Nitrogen

(TKN) increased 13% in 2024.

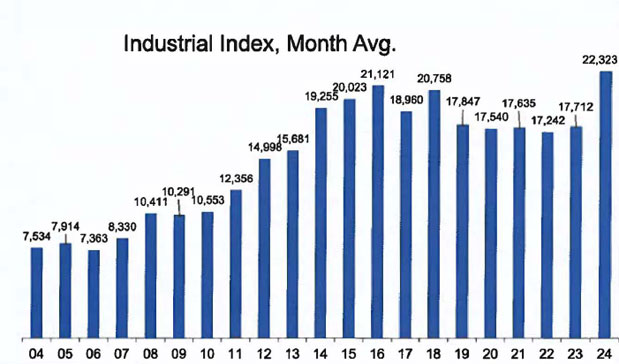

Finally, in order to measure the relative strength of the industrial waste, staff developed a

formula that combines TSS, BOD and TKN data. The resulting value, Industrial Index,

provides a single numeric number. The Industrial Index increased by 26% in 2024.

Overall, Industrial wastewater conveyed to GJJWTF via the sanitary sewer increased in 2024.

The industrial index system does not incorporate the following wastewater streams:

-

Whey directly piped to the anaerobic digesters;

-

National Grid remediation discharges;

-

Fulton County Department of Solid Waste’s leachate.

As shown in the graphs, industrial loadings to GJJWTF increased over the previous year, Total

Industrial Flows decreased 7.26%, Total suspended solids (TSS) increased 32.58%, Biological

Oxygen Demand (BOD) increased 23.6%. Total Kjeldahl Nitrogen (TKN) increased 15.38% in

2024.

Contract Renewals

- Fonda Municipal Sludge Contract

- St Johnsville Municipal Sludge Contract

- Mayfield Municipal Sludge Contract

- Precision Industrial Septic Hauler Contact

- Fulton County Landfill Leachate Contract

PLANT LOADINGS

| 2024 Industrial loadings (Total, Includes Dairy): |

2023 Dairy Loadings: |

|

|

|

| |

FLOW: |

320,048,358 gals |

|

188,472,752 gals

|

| |

BOD: |

5,281,955 lbs |

|

3,766,461 lbs |

| |

TSS: |

1,985,099 lbs |

|

1,195,087 lbs |

| |

TKN: |

264,586 lbs |

|

160,046 lbs |

2024 Dairy Wastewater Loadings:

214,511,924 gals

4,665,914Ibs

1 ,656,757 Ibs

188,011 Ibs

Dairy accounted for

67.0% of Industrial Flow

88.3% of Industrial BOD

83.5% of Industrial TSS

71 .1 % of Industrial TKN

Dairy COD strengths for whey are as follows:

|

FAGE

|

Euphrates

|

Blended

|

|

(mg/L)

|

(mg/L)

|

(mg/L)

|

|

123844

|

120,952

|

58,792

|

FAGE's yogurt product creates a relatively low COD strength whey byproduct.

Euphrates' feta cheese product creates a relatively higher COD strength whey byproduct.

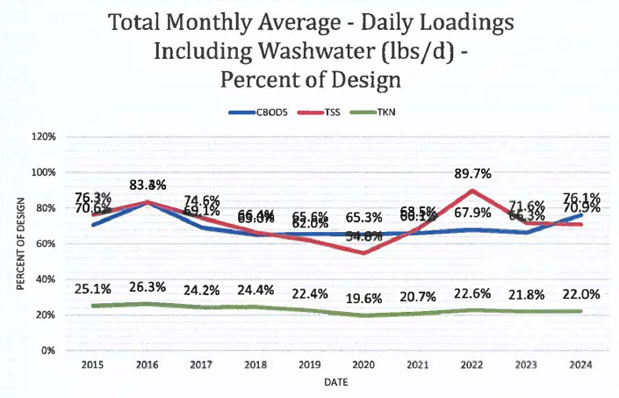

Comparison of Facility's 2024 Total Plant Dally loadings (NOT Including Washwater) relative to

Design loads:

-

CBOD daily loadings (Ibs/d), averaged monthly, equaled 35.5% of GJJWTF's designed

CBOD load. March was highest at 43.0% of design load. August was lowest at 28.7% of

design load.

-

TSS daily loadings (Ibs/d), averaged monthly, equaled 51.8% of GJJWTF's designed TSS

load. March was highest at 130.1% of design load. September was lowest at 33.7% of

design load.

-

TKN daily loadings (Ibs/d), averaged monthly, equaled 16.6% of GJJWTF's designed TKN

load. March was highest at 27.2% of design load. October and November were lowest at

12.6% of design load.

GJJWTF continues to operate below its design loadings. Therefore, GJJWTF can accept future

wastewater loads from the community at large andlor new industries/businesses.

OPERATIONS

The year-to-year removal efficiency rates for the GJJWTF are as follows:

|

Parameters

|

2018

|

2019

|

2020

|

2021

|

2022

|

2023

|

2024

|

|

Total Suspended Solids

|

97%

|

97%

|

97%

|

98%

|

98%

|

98%

|

97%

|

|

Biochemical Oxygen Demand

|

98%

|

98%

|

98%

|

98%

|

98%

|

98%

|

97%

|

|

Total Kjeldahl Nitrogen

|

93%

|

92%

|

93%

|

93%

|

93%

|

92%

|

92%

|

As shown in the Table, the TSS and BOD removal efficiencies are greater than the permitted

removal rate of 85% prior to discharge to Cayadutta Creek.

Belt Filter Presses (BFPs) operated 3,439 hours producing 17,814 wet tons of sludge (2.8%,↑).

During 2024, sand and/or dried sludge was blended into the sludge cake to meet the minimum

20% solids landfill disposal requirement.

Together, the BFPs and Gravity Belt Thickeners (GBTs) utilized 45,375 pounds of polymer

(2.9%,,J...). In addition, the BFPs used another 7,770 gallons of an emulsion polymer (17.4%,↑)

to enhance sludge dewaterability.

GJJWTF purchased 31,811 gallons of Ferrous Chloride (7.6%,↑) to control sulfides at the anaerobic digesters. GJJWTF also purchased 41,579 therms of Natural gas to heat various buildings (17.0%,↓).

BACKFLOW PREVENTERS

Adirondack Mechanical Corporation tested all backflow preventers on-site. Nine (9) backflow

preventers keep the Facility's effluent from entering and contaminating the City's drinking water

supply. All but two (2) backflow preventers passed the annual testing. The two which failed are

in the Sludge Building Garage, and the second is located in the Maintenance Garage. The

connection downstream of the Backflow Preventer where city water interconnects with Effluent

Process Water is isolated. Working with Adirondack to source replacement Backflow Preventers.

LEACHATE

GJJWTF received and processed 17.2 million gallons of leachate. The Fulton County Landfill

pumps leachate to the facility via a dedicated six (6) mile long force main. Leachate contains

699.3 mg/L of TKN. This equates to over 100,325 Ibs/year.

RENEWABLE ENERGY – CLIMATE CHANGE

The Dairy Industry pumped 29,376,468 gallons of whey via a dedicated pipeline direcUy to two

(2) whey storage tanks located at GJJWTF. From these tanks, operators pump the whey at a

constant feed rate to the anaerobic digesters. Then, anaerobic bacteria break down the whey

and expire large quantities of digester gas (- 56% Methane and 44% Carbon Dioxide).

A direct result of GJJWTF's cogeneration philosophy is the significant reduction towards our

dependence upon natural gas. The Anaerobic Digesters produced 181 million cubic feet of

biogas from the whey, CAST Settleable Solids, Primary Sludge and Waste Activated Sludge.

GJJWTF's biogas generators consumed 23.4% of this biogas to generate

2.23 million kilowatt

hours of electricity. Our electrical production meant that less energy was required to be supplied

and purchased from external sources.

FINANCE OFFICE

The 2024 Financial Audit Summary from BST & Co. CPAs, LLP disclosed no issues of

noncompliance, and no alternative procedures or corrective actions were suggested.

O&M revenues totaled $6.4 million during 2024, including $1.2 million in insurance recovery. The

Industrial contribution was 48.18%, Residential 29.03%, and Trucked/Pumped waste and

miscellaneous revenue totaled 22.79%.

Sewer rates were adopted after a public hearing. Residential sewer rates increased 10.8%.

INDUSTRIAL USE

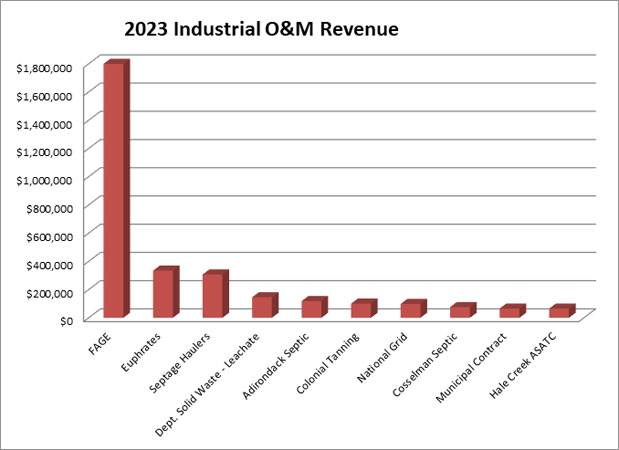

O&M revenue from industrial users increased 10.04% in 2024.

Dairy Industry accounted for the top two (2) facility users. FAGE USA Dairy Industry, Inc.

continued as the Number 1 user and Euphrates Inc. as the second largest user.

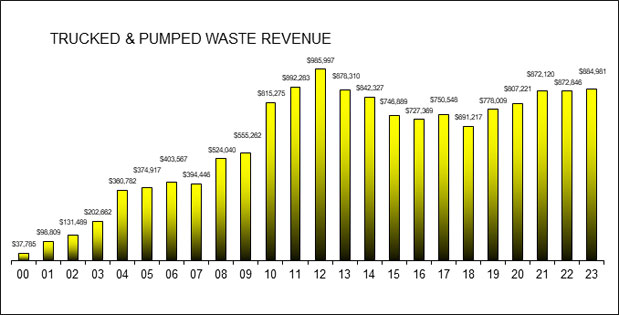

Septic Haulers as a group are the third largest user of the wastewater facility. Two (2) trucked

waste accounts (Adirondack Septic and Cosselman Septic) in order of rank are part of the Septic

Haulers category.

The leather Industry, Colonial Tanning and Townsend, are included in the top ten revenue

producers.

Fulton County Department of Solid Waste, National Grid remediation site, MuniCipal Contracts

and Hale Creek ASATCA round out the top largest customers of the facility in 2024.

State Asset Management Program

GJJWTF volunteered for this NYS DEC Program to improve our commitment to service with the

sewer users in 2022. This process has been resurrected, and the facility has been working closely

with C2AE the engineering firm retained by the NYSDEC to develop the Asset Management

Program for GJJWTF. There has been tremendous progress made in 2024, GJJWTF is now

back on schedule. Have also had several interactions with NYSDEC to review our current

progress and have reaffirmed our commitment to this program.

Return To Top

|